|

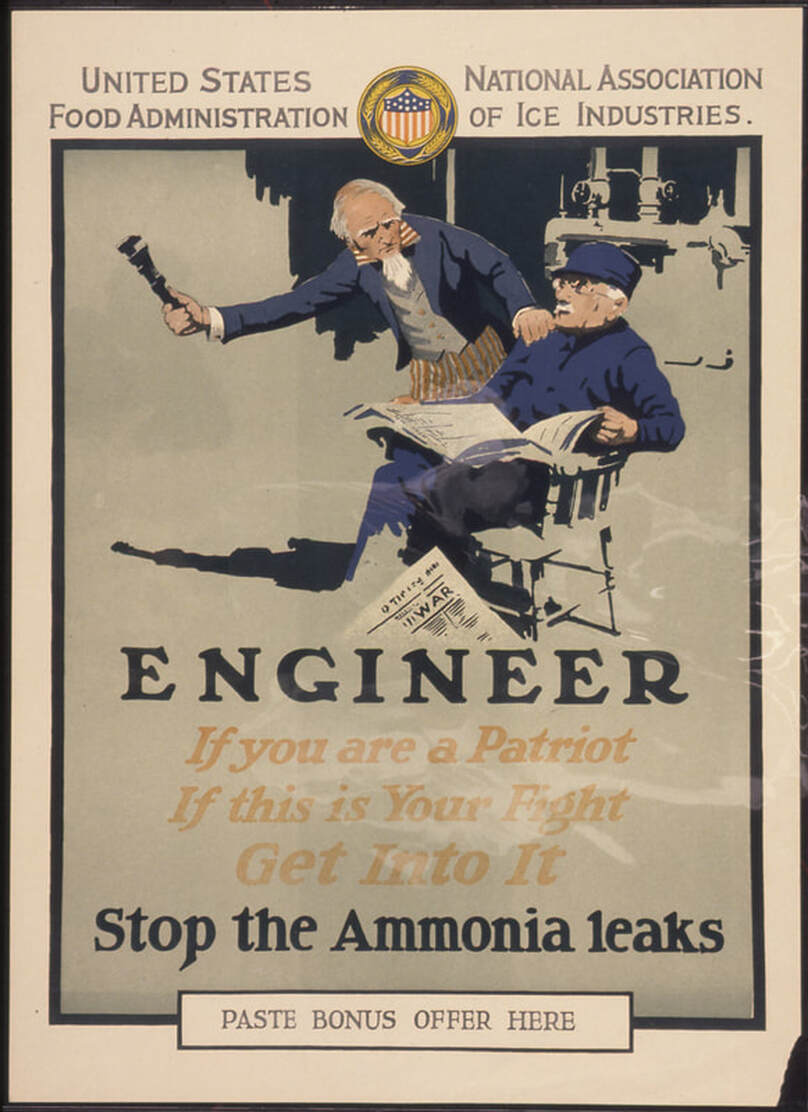

You may be wondering, what on earth do ammonia and engineers have to do with food history? Well, ammonia was one of the primary ingredients in creating artificial ice in the late 19th and early 20th centuries. The poster above shows Uncle Sam brandishing a wrench, hand on the shoulder of an older engineer, who reclines in a chair reading the newspaper. One sheet of the newspaper has fallen to the floor, and we can make out "War" in the headline. In the background we can see the outlines of pipes and valves. The poster reads "ENGINEER - If you are a patriot, If this is your fight, Get Into It - Stop the Ammonia Leaks." The top of the poster indicates it was sponsored by both the United States Food Administration and the National Association of Ice Industries. Refrigeration was changing rapidly in the 1900s. Most of the country still refrigerated with "natural ice," or ice harvested in winter from freshwater sources like lakes and rivers. But "artificial ice," that is water frozen mechanically, was gaining ground. Artificial ice making factories had been around since the 1870s, but they were costly and inefficient, used primarily in warmer climes where shipping natural ice was too inefficient. The primary refrigerant in these factories was ammonia, which has explosive properties. In fact, ammonia is a primary component in making gunpowder and explosives, and obviously demand for its use went up exponentially when the U.S. joined the First World War in April of 1917. Ammonia cools through compression. Jonathan Reese in Before the Refrigerator: How We Used to Get Ice (Amazon affiliate link) explains the process: The compression refrigeration cycle depends on the compressor forcing a refrigerant around a system of coils. A refrigerant is any substance that can be used to draw heat away from an adjoining space, but some refrigerants worked much better than others. During the late nineteenth century, most American refrigerating machines used ammonia as their refrigerant. The main advantage of ammonia was that it was very efficient. In other words, it has a very low vaporizing temperature (or boiling point) at which it will turn from a liquid into a gas. This means that it required less energy to propel it through the cycle and remove heat from whatever space or substance that the operator needed to become cold. If ammonia leaked through the pipes of these early machines (which it was prone to do), under certain circumstances it could even explode, as the New York packing house example described above illustrates.¹⁰ Most American refrigerating equipment manufacturers didn’t realize that until ammonia compression refrigeration systems had become extremely popular.¹¹ Cold storage also increased in use during the First World War, and refrigerated railroad cars, which helped drive agricultural specialization in fruits and vegetables around the country (Georgia peaches, Florida oranges, Michigan cherries, New York apples, and California's salad bowl), depended on ice for refrigeration and cooling. Ice was the invisible ingredient in the nation's food system. The National Association of Ice Industries was founded in August, 1917 in Chicago, IL as ice harvesters, producers, and distributors gathered at a conference. Realizing the importance of the ice trade in food preservation and conservation, the association vowed to cooperate with the government as part of the war effort. The conference proceedings were reported in Refrigerating World, the industry's trade journal, in the September, 1917 issue. In addition to forming the National Association of Ice Industries on the second day of the conference, the attendees also discussed convincing farmers of the benefits of cold storage and encouraging them to construct ice houses on their farms, of convincing the public that using ice and refrigeration would reduce food waste and save money, and finally of reducing inefficiencies in delivery, including advocating for one delivery service making one delivery per day to prevent competing delivery companies from wasting manpower, horsepower, and ice. Wartime not only necessitated the conservation of ammonia, but also gave the natural ice industry a boost. Already in decline due to concerns about polluted waterways, the natural ice industry was encouraged to revive as another way to conserve ammonia and the fuel that powered the steam engines and electric motors that powered the refrigerating process. The revival would ultimately be short-lived. The end of the First World War all but ended the natural ice industry. As refrigerants became abundant again and energy prices came back down, the demand for artificial ice went up. The advent of electric home refrigerators in the 1920s ultimately signaled the end of the household ice box, and the deliveries that went with it. Read More: The Amazon affiliate links below help support The Food Historian

1 Comment

Jeff Sloan

5/23/2023 07:22:22 pm

Several inaccuracies about how refrigeration works and about ammonia in general. I have been teaching industrial refrigeration for over 20 years and have been involved in the industry for over 40.

Reply

Your comment will be posted after it is approved.

Leave a Reply. |

AuthorSarah Wassberg Johnson has an MA in Public History from the University at Albany and studies early 20th century food history. Archives

July 2024

Categories

All

|

RSS Feed

RSS Feed